Scientific goals and objectives

Our high-pressure laboratories are used to investigate biogeochemical, geomechanical and geotechnical processes in marine sediments. The different experimental systems can be operated at high hydrostatic pressure (up to 40 MPa), a wide temperature range and under dynamic fluid flow conditions, which is necessary to simulate relevant deep-sea conditions and scenarios. Furthermore, the systems allow to apply and control mechanical loads and stresses to investigate sediment strength and stress-strain behavior under complex thermo-hydro-chemo-mechanical (THCM) process coupling. Process monitoring and analysis is based on using different online monitoring techniques and sensors (e.g. Raman and infrared gas sensors, local deformation and strain measurement, distributed in situ pressure-temperature sensors), and high-resolution imaging tools (e.g. X-ray CT and ERT).

The experimental systems are used for a large variety of research topics, including:

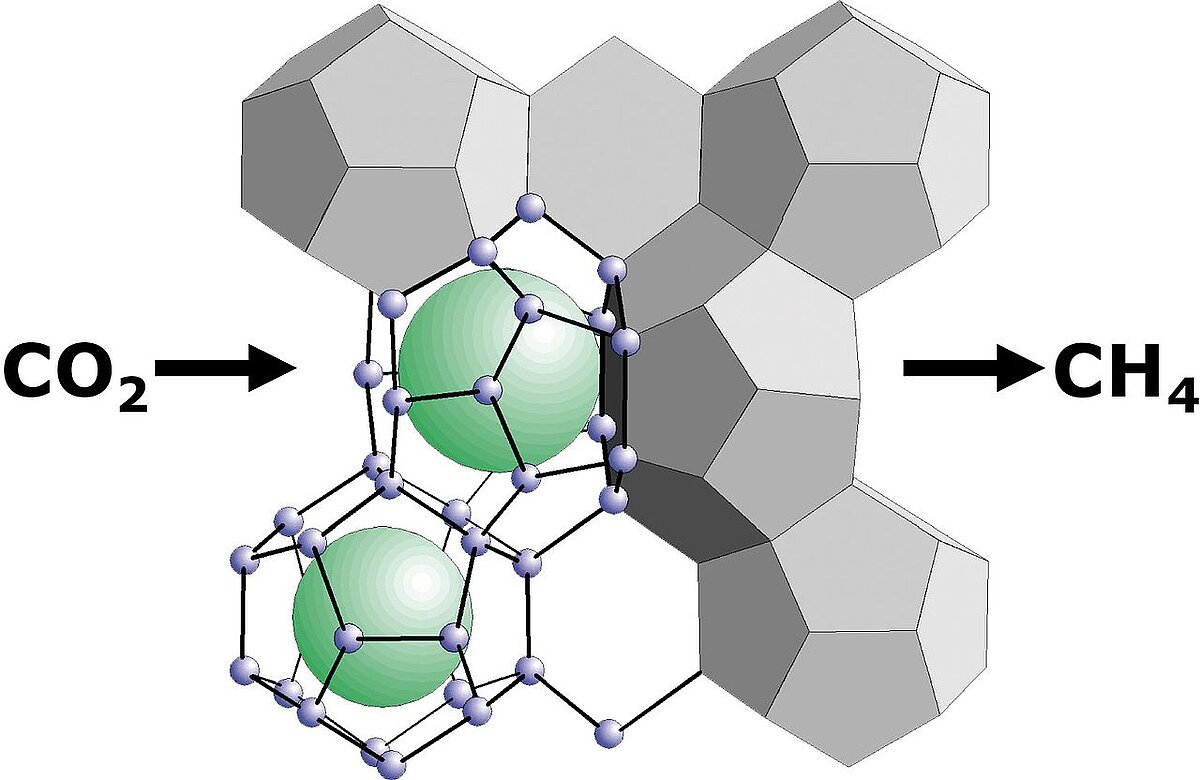

* Investigation of mechanisms and effects of formation, dissociation and conversion of gas hydrates in sediments

* Analysis of multiphase flow in sediments and rocks to characterize fluid migration at gas seeps or resulting from technical leakage

* Investigation of geotechnical risks of sediment destabilization and slope failure, and process development for sediment stabilization

* Simulation of transport-reaction processes in potential storage scenarios (e.g. CO2-fluid-sediment interactions and weathering reactions) and deep-sea mining

* Analysis of microbial processes in marine sediments (e.g. AOM and hydrocarbon degradation, microbial iron and manganese reduction, sulfate reduction and methanogenesis)