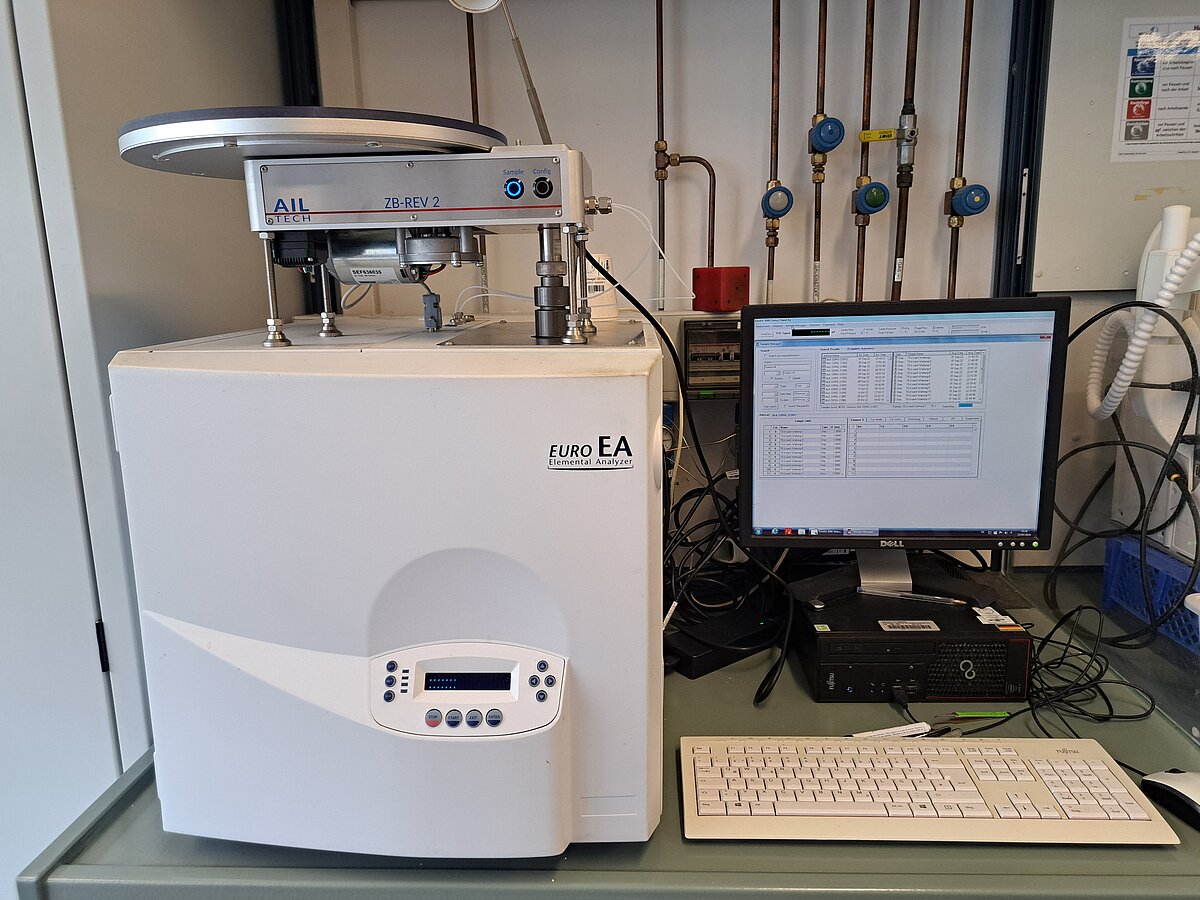

Determination of CNS in sediment samples with the Euro EA 3000 Elemental Analyzer

Until May 2016 the determination of CNS in sediment samples was done with the CARLO ERBA Elemental Analyzer

The method described here is based on a complete oxidation of the elements and a subsequent chromatographic separation of the oxidation gases. Detection is carried out by a thermal conductivity detector. The analysis is fully automatic and requires 7.5 minutes of analysis time to determine a sample. The sample weighed into a tin capsule (TC/N/S) or a silver capsule (Corg) is introduced into the reaction tube by the automatic sampler. There the sample is burned with the addition of oxygen and supported by the exothermic oxidation of the tin capsule. Helium as a carrier gas transports the reaction gases (N2, NOx, CO2, H2O, SO3 and SO3) over tungsten oxide as an oxidation catalyst in the upper part of the reactor, then over copper in the lower part. On the copper, NOx is reduced to N2 and SO3 to SO2 .The reaction gases are separated in a chromatographic separation column and detected with a thermal conductivity detector. The areas of the peaks are integrated by the data system and converted into concentrations using the calibration data.

Operating Parameter for CNS-analyses

Carrier: 60kPa

Purge: 100ml/min

Oxygen: 12ml

delta PO2: 25kPa

Oxidation time: 5,5sec

Sample Delay: 6 sec

Run time: 450 sec

Front Furnace: 1000°C

GC Oven: 75°C

Column filling reaction tube: copper for sulfur analysis and tungsten oxide on aluminum oxide

Sample Preparation:

The freeze dried samples are ground whether in an agate mortar or in a mill. For sulphur measurements samples should be ground in a mill. Depending of the C/N/S concentration, 3-20mg of sample is weighed into a tin capsule (C/N/S) or silver capsule for the measurement of tje organic carbon (Corg). For sulphur determination the same amount of Vanadiumpentoxid is added to the sample. Organic carbon is determined after removing carbonate carbon by acidification with 0,5N hydrochloric acid and drying on a hot plate (max. 100°C), until no more bubbles appear in the sample.

Calibration:

For each set of samples (n = 50) Standards and blanks are measured.

Calibration Standards TC/N

Acetanilid N:10,36%,C:71,09 %

SOIL Standard BSTD1: N:0,216%, C:3,5 %

Calibration Standard TC/N/S

BBOT 2,5-Bis(5tert-butyl-2-benzo-oxal-2-yl)thiophen :C:72,52%,N:6,51%,S:7,44%

Measurements:

Each sample is run as a duplicate, for long term precision calculation an internal standard is measured in each set.

Statistic

Relative Standard- Deviation:

TC/N/S : Sample SO 143 55-5- 56-58 cm (n=5)

% N % C %S

MEAN 0,145 1,930 0,984

Standard Deviation 0,002 0,012 0,034

Relative Standard Deviation (%) 1,427 0,610 3,467

Precision

STANDARD:BBOT

% N % C %S

MEAN 6,509 72,654 7,593 n = 5

Standard Deviation 0,110 0,872 0,166

Relative StandardDeviation % 1,689 1,200 2,182

Accuracy 1,69 1,2 2,18

Certified concentration 6,510 72,52 7,44

Detection limit:

C:0,94µg

N: 0,23 µg

S: 0,06µg

Quantification limit

C: 3,14 µg

N: 0,76µg

S: 0,20 µg

Standard used for C/N Measurements: BSTD 1 C:3,5%, N:0,216%

Standard used for S Measurements: BBOT

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Determination of CNS in sediment samples with the CARLO ERBA Elemental Analyzer (until May 2016)

This instrument analyzes total carbon, nitrogen and sulphur in solid samples. The analytical method is based on the complete and instantaneous oxidation of the sample by „flash combustion“ which converts all organic and inorganic substances into combustion products. The resulting combustion gases pass through a reduction furnace and are swept into the chromatographic column by the carrier gas (helium) The gases are separated in the column and detected by the thermal conductivity detector (TCD) which gives an output signal proportional to the concentration of the individual components of the mixture.

The sample to be analyzed is weighed into a tin capsule (TC/N/S) or in a silver capsule (Corg) and loaded into the autosampler. The sample falls into the Combustion reactor which is maintained at around 1050°C. The sample container melts and the tin promotes a strong reaction (flash combustion) in a temporary enriched atmosphere of oxygen. The combustion products (N2,NOx,CO2,H2O,SO2 and SO3), carried by a constant flow of carrier gas (Helium) pass through an oxidation catalyst of Tungsten oxide on Alumina, kept at 1050°C inside the reaction combustiontube. Furthermore, to ensure the complete oxidation, a 5 cm layer of silver coated cobalt oxide is placed at the bottom of the combustion tube. The catalyst also retains interfering substances, produced during the combustion of halogenated compounds.

The mixture of combustion products and water passes through a second tube known as the reduction reactor which contains metallic copper kept at 650 °C. The excess oxygen is removed in the reaction reactor and at this temperature the nitrogen oxides coming from the combustion tube are reduced to elemental nitrogen, which together with carbon dioxide, sulphur dioxide and water pass trough the asorbent filter.

Note that the packing of the combustion tube for N/C/S determination differs from the one used for TC/N analysis. The combustion products pass through only one tube filled with the oxidation catalyst (Al2O3with WO3), and a 6 cm layer of pure copper wire is placed at the bottom of the combustion tube.

Operating Parameter for TC/N analyses

Oxidation furnace temperature 1050°C

Reduction furnace temperature 650°C

GC column oven and detector block temperature 75°C

Filament temperature 190°C

Helium carrier gas flow rate (main) 80ml/min

Helium carrier gas flow rate (reference) 40ml/min

Oxygen flow rate 25ml / min

Total analytical time 240 sec

Reactor packing for TC/N:

Combustion reactor: Chromium Oxide/Silvered cobaltous cobaltic oxide

Reduction reactor copper

Operating Parameter for N/C/S analyses

Oxidation furnace temperature 1060°C

GC column oven and detector block temperature 75°C

Filament temperature 190°C

Helium carrier gas flow rate (main) 95ml/min

Helium carrier gas flow rate (reference) 40ml/min

Oxygen flow rate 10ml in 9,5 sec

Total analytical time 740 sec

Reactor packing for simultaneous determination of N/C/S

Pure reduced copper wires

And as OXIDATION CATALYST Al2O3 + WO3

Or Tungstic Anhydride

Sample Preparation:

The freeze dried sample are grinded whether in an agate mortar or in a mill. For sulphur measurements samples should be grinded in a mill. Depending of the C/N/S concentration, 3-20mg of sample is weighed into a tin cup (N/C/S) or silver cup for the TOC measurements. For sulphur determination the same amount of Vanadiumpentoxid is added to the sample. Organic carbon is determined after removing carbonate carbon by acidification with 0,25N hydrochloric acid.

Calibration:

For each set of samples (n = 50) Standards and blanks are measured.

Calibration Standards TC/N

Acetanilid N:10,36%,C:71,09 %

SOIL Standard BSTD1: N:0,216%, C:3,5 %

Calibration Standard TC/N/S

BBOT 2,5-Bis(5tert-butyl-2-benzo-oxal-2-yl)thiophen :C:72,52%,N:6,51%,S:7,44%

Measurements:

Each sample is run as a duplicate, for long term precision calculation an internal standard is measured in each set.

To top